Feature

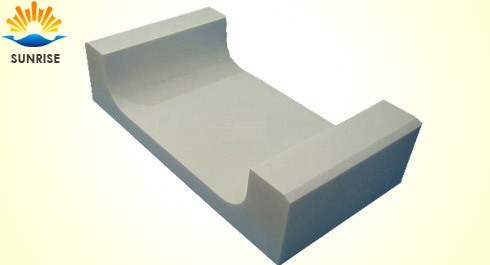

Fused cast Alumina Block TY-M Description

Fused cast Alumina Block TY-M is formed by the compact structure of alpha alumina and beta alumina crystals in a most ideal proportion which is approximately 50% and 50% respectively,where intertwined crystals of both materials result in a very dense structure.TY-M has dense structure and no contamination to glass. It is the ideal refractory materials for channels, spouts and working ends of floating glass furnace.

Specifications and applications

--Below 1350 ℃, it has excellent corrosion resistance against molten glass and great performance against contamination to molten glass, thus it is very suitable for paving blocks and fore-hearth channel blocks.

--When in contact with molten glass, it barely produces any blistering or stones. So, α-β alumina blocks may be widely used in working tank, feeder channels, superstructures and lipstone, etc.

--In general, in soda-lime container furnaces α-β alumina fused-cast is installed in the Alcove and channel areas, as alternative to AZS fused-cast for Alcoves and as alternative to AZS fused-cast, zirmul, sinter-alumina and other sinter refractories for channels.

--In the float furnaces fused-cast α-β alumina is widely installed in the glass contact (sidewall and pavers) from the waist through the refining area up to spout and lip included.

Technical Data

| Item | FUSED CAST ALUMINA | |

| α-β Alumina TY-M | ||

| Chemical Composition % | Al2O3 | 94 |

| SiO2 | 1 | |

| NaO2 | 4 | |

| Other oxides | 1 | |

| Crystallographic Analysis % | α-Al2O3 | 44 |

| β-Al2O3 | 55 | |

| Vitreous Phase | 1 | |

Inquiry